$115M for Vertical Farm’s Biotech Leap, World’s First Microbial Oil Milestone, and $18M for Sweet Proteins

Also: Alt proteins could contribute €65B to the German economy and create up to 250,000 new jobs by 2045

Hey, welcome to issue #92 of the Better Bioeconomy newsletter. Thanks for being here!

Last week, James Ryall featured me in his newsletter, where I had the chance to reflect on my journey from a 12-year-old fascinated by glowing carrots to working in agrifood tech VC!

During our chat, I shared about:

🧬 How a substitute teacher sparked my biotech obsession

👨🏾🔬 Why I decided to pursue a career in commercial biotech over academia

🍔 How the pandemic and food security concerns led me to food tech and alt proteins

✉️ The story behind this newsletter and why I write "for myself"

🥳 Landing my ‘dream role’ (cliche, I know) at Better Bite Ventures

🤩 Emerging trends in biomanufacturing that get me excited

A huge thank you to James for telling my story! If you're into biomanufacturing and food tech, his newsletter is a must-read. Check out the full write-up here.

Alright, let’s dig into the latest updates on the intersection of biotech and agrifood!

BIO BUZZ

Products, partnerships, and regulations

🇳🇱 NoPalm Ingredients achieved the ‘world's first’ industrial-scale yeast oil fermentation using upcycled side streams for oil and fat production

In just three years, production scaled from small lab experiments to 5,000 litres last summer and now 120,000 litres, proving that sustainable oils and fats can be commercially produced.

The Dutch startup’s fermentation-based oil is a direct replacement for palm oil, helping reduce deforestation while remaining cost-competitive and reinforcing a circular economy.

NoPalm is now conducting large-scale testing with commercial partners, working to secure contracts and build a first-of-its-kind demonstration factory to begin full-scale production.

Source: vegconomist

🇮🇱 Finally Foods set to conduct its first field trial for casein-producing potatoes just 10 months after launching

In what the Israeli molecular farming startup calls “record time,” it will begin its first field trial for potatoes containing dairy proteins in Israel soon. The trial, lasting 3-4 months, will assess the scalability of casein production in potatoes.

The company uses Evogene’s GeneRator AI to streamline R&D, boost extraction efficiency, and scale production. Integrating AI allowed Finally Foods to accelerate development, reduce costs, and increase casein yields in potatoes.

This field trial is a big step toward regulatory approval. It provides necessary data on casein-producing potatoes' environmental impact and large-scale agricultural feasibility. A prior greenhouse trial confirmed that these genetically modified potatoes grow like regular ones.

Source: Green Queen

🇺🇸 PFerrinX26, backed by Earth First Food Ventures, enters the lactoferrin market with a precision fermentation facility

Lactoferrin is an iron-binding antimicrobial protein found in mammalian milk. It supports immunity, iron regulation, digestion, endurance, and muscle strength. However, it has traditionally been difficult to source due to the high milk volume required for extraction.

Earth First Food Ventures (EFFV) is assembling a group of big dairy, dextrose suppliers, CPG companies, and ingredient players to fund and support the facility. Unlike other precision-fermented lactoferrin companies, EFFV prioritizes in-house production rather than co-manufacturing agreements.

While exploring dairy proteins like beta-lactoglobulin (a prevalent whey protein), the company prioritizes lactoferrin because of its high market value and minimal amounts needed in key applications.

Source: AgFunder

🇳🇱 Cultivated pork pioneer Meatable broadens its horizons beyond food through an animal-free leather partnership

As it awaits regulatory approval in Singapore for its cultivated meat, the Dutch company is diversifying into materials. Meatable partnered with Pelagen, a cell-based leather company, to improve the production of sustainable leather for industries such as fashion, automotive, and interior design.

Meatable's Opti-ox technology eliminates the need for fetal bovine serum. It uses pluripotent stem cells to rapidly multiply and generate high cell densities. Opti-ox allows Meatable to produce cultivated muscle and fat cells in just 12 days, compared to eight months for pigs and 2–3 years for cows.

Unlike traditional synthetic leather made from petroleum-based plastics, which can take up to 500 years to degrade, cultivated leather significantly reduces greenhouse gas emissions, microplastic pollution, and waste.

Source: Green Queen

🇩🇪 Alt proteins could contribute €65B to the German economy and create up to 250,000 new jobs by 2045

A new study by Systemiq finds that the country's domestic alt protein market could reach €10B by 2030 and €23B by 2045 in a high-ambition scenario. The total export opportunity could reach up to €15B by 2030 and €35B by 2045.

Under the conservative scenario, 45,000 jobs could be created by 2030 and 115,000 by 2045. In a high-ambition scenario, job creation could reach 95,000 by 2030 and 250,000 by 2045.

The country’s strengths lie in food production and machinery, such as extruders and fermentors, for global exports. Without strong policy support, though, Germany risks falling behind in global competition. Strategic investments could secure its leadership in protein diversification.

Source: Good Food Institute Europe

BIO BUCKS

Funding, M&As, and grants

🇺🇸 Oobli raised $18M in Series B1 and partnered with Ingredion to co-develop sugar alternatives using sweet proteins

The California-based startup uses precision fermentation to produce brazzein, a sweet protein that is up to 2,000x sweeter than sucrose. These proteins can replace more than 70% of sugar in foods and beverages without impacting blood sugar, insulin, or gut health.

In March 2024, Oobli received FDA clearance to sell brazzein and monellin, another ultra-sweet protein. The company is expanding through partnerships with brands like Group Bimbo, with several new products set to launch in 2025.

Oobli and Ingredion are testing new sugar alternatives and will showcase them at Future Food Tech next month. They aim to create cost-effective, natural sweeteners that help food companies meet nutritional goals while maintaining taste.

💰 Investors: Ingredion Ventures, Lever VC, Sucden Ventures, Khosla Ventures, Piva Capital, and B37 Ventures

Source: Green Queen

🇺🇸🇮🇱 80 Acres Farms raised $115M and acquired biotech company Plantae Biosciences to advance plant genetics for indoor farming

Most crops today are bred for outdoor farming, prioritizing drought and pest resistance over traits like flavour and nutrition. The US-based vertical farming company aims to develop crops specifically for controlled environments where some of these outdoor adaptations are unnecessary.

Using Israel-based Plantae’s metabolomics and genome editing, 80 Acres can accelerate crop breeding from decades to just a few years, improving flavour, texture, and nutrition.

80 Acres sees plant genetics as the next big innovation in vertical farming. By engineering crops for better taste, texture, and nutrition, they can differentiate produce quality compared to traditional farming.

💰 Investors: General Atlantic, Siemens Financial Services, The Western and Southern Life Insurance Company, Barclays Climate Ventures, Virgo Investment Group, and more.

Source: AgFunder

🇮🇱 IBI Ag secured $6.1M in the first tranche of its Series A funding to develop bioinsecticides using ultra-small antibodies

By developing antibodies that are 10x smaller than conventional ones, the Israel-based company produces a higher concentration of active ingredients at a lower cost, making its products more affordable for farmers.

The nanobody-based bioinsecticides are highly stable, biodegradable, and do not harm beneficial insects or the environment, addressing concerns linked to chemical pesticides.

Currently conducting field trials, IBI Ag plans to seek regulatory approval in the US by the end of the year. The company also aims for further expansion into Latin America, where regulations are more favourable for biologicals.

💰 Investors: Corteva Catalyst, Trendlines Group, Iron Nation, Consensus Business Group, and Israel Innovation Authority (grant).

Source: AgFunder

🇺🇸 16-year-old founder's company raised $3.5M in seed funding to use biochar to increase crop yields while removing CO2

CarbonZero.Eco, a Silicon Valley-based startup focused on regenerative agriculture and CO2 removal via biochar, received backing from executives and managers at Google, Meta, Amazon, and late-stage startup CEOs.

The company has already secured $7M in agreements with 300 almond farms in California, aiming to mitigate 1.5M tons of CO2 emissions from agricultural waste decomposition.

Agriculture generates 1,300M tons of waste annually, with current disposal methods contributing 3% of global greenhouse gas emissions. Biochar, supported by 6,000+ studies, locks carbon away for thousands of years while improving soil fertility and productivity.

Source: PR Newswire

🤑 More bucks

🇬🇧 CroBio secured €805k from the UK’s Defra through the Farming Innovation Programme to develop its microbial soil health tech. The funding will accelerate research on a treatment that generates absorbent bacterial cellulose, enhancing soil quality by retaining water and nutrients. (Agritech Digest)

🇦🇺 Magic Valley, an Australian cultivated meat startup, received a $100k grant from the federal government’s Industry Growth Program (IGP). The funding will support scaling of production, optimisation of bioprocessing, and reducing costs, all of which help towards commercial viability. (vegconomist)

GEEK ZONE

Scientific research papers

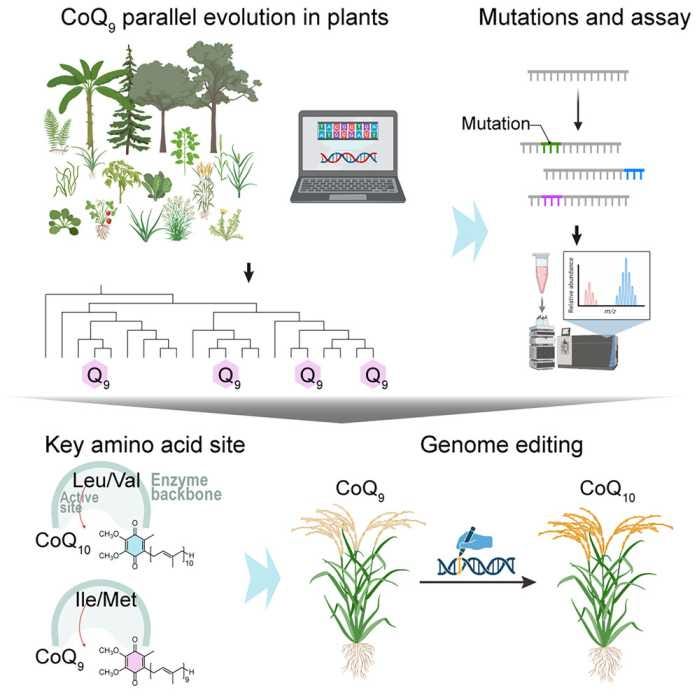

🌾 CRISPR-edited rice produces CoQ10 which supports heart and cellular health

Scientists identified the key genetic factors controlling CoQ10 levels and used CRISPR gene editing to modify the Coq1 gene in rice and wheat. This modification successfully converted CoQ9 to CoQ10 without significantly impacting crop yield.

CoQ10 is crucial for mitochondrial function and cardiovascular health, and its levels decrease with ageing and certain medications (like statins). Engineering CoQ10-rich crops could provide a natural dietary source, reducing reliance on supplements.

The study provides a blueprint for editing other crops (such as corn, spinach, and lettuce) to increase CoQ10 production. Future research will explore whether higher CoQ10 levels can help plants resist environmental stress, such as drought or extreme temperatures.

Source: Cell

♻️ Novel approach for food waste valorization to value-added products through enzymatic hydrolysis with plant ash and biochar

The study introduced a 12-hour enzymatic hydrolysis process using fungal mash by combining plant ash and biochar. It generated two products: a solid biofertilizer and a liquid solution that could be used as a carbon source for denitrification.

The liquid component achieved concentration levels of 170 g/L and demonstrated high nitrogen removal capabilities, with rates of 26.23-31.33 mg N/g MLVSS/h compared to commercial glucose's 25.92 mg N/g MLVSS/h.

Testing of the solid biofertilizer showed improvement in plant germination, boosting rates by up to 166% compared to 122% in untreated samples, demonstrating the approach’s potential in creating a complete resource recycling system with zero waste discharge.

Source: Bioresource Technology

🌱 Siderophores from beneficial bacteria improve iron availability and boost immunity to improve disease resistance in mung bean plants

The study found that siderophores (iron-binding molecules) from Bacillus amyloliquefaciens help mung beans fight Cercospora leaf spot disease. Plants treated with siderophores showed higher activity in key defence enzymes, including peroxidase, polyphenol oxidase, and chitinase.

Siderophores triggered a 21.1x increase in catalase gene expression, which rose to 25.9x when combined with pathogen exposure, making plants more resilient to oxidative stress. Epoxide hydrolase and PR10 genes, linked to plant immunity, were also significantly activated.

Siderophores facilitate iron uptake and enhance plant immunity, positioning them as a natural alternative to chemical fungicides. However, field testing is required to confirm their practical benefits in real-world farming conditions.

Source: Frontiers in Microbiology

💨 Dried food waste improved biohydrogen production through process optimization and microbial fermentation

The study explored the production of biohydrogen from dried food waste (DFW) and its hydrolysate (DFWH) through dark fermentation. Particle analysis showed 60% of DFWH's volume density had particles smaller than 0.01 μm, confirming successful biomass breakdown and improved enzyme access.

DFWH produced 1.24 mol H₂ per mol of glucose equivalent, a 1.58x increase compared to untreated DFW. However, untreated DFW had the shortest lag time, 14.6 hours, meaning microbes adapted to it faster.

Microbial analysis of DFWH showed a composition dominated by hydrogen-producing bacteria Clostridium puniceum and Clostridium butyricum, supported by sufficient micronutrients. This indicates DFWH's potential as a sustainable biohydrogen feedstock.

Source: Journal of Environmental Management

EAR FOOD

Podcast episode of the week

🎧 Why biomanufacturing is the key to sustainable space colonization

Guest: Erika DeBenedictis, CEO of Pioneer Labs

Biomanufacturing as the key to space colonization: Traditional "camping trip" space missions where everything is packed and brought from Earth are unsustainable for Mars. To enable long-term human habitation, biology must be integrated into space missions to transform local resources into food, building materials, oxygen, and even rocket fuel.

Dual-use breakthroughs: Technologies developed for Mars, such as microbes engineered for extreme environments and robust bioprocessing systems, will have direct applications on Earth. These innovations can enhance terrestrial biomanufacturing, enabling lower-cost fermentation, sustainable agriculture, and resilient bio-based supply chains.

Mars as a testbed for ‘net positive’ civilization: Unlike Earth, where legacy infrastructure locks us into unsustainable systems, Mars offers a clean slate. Space settlement forces the adoption of circular, regenerative biomanufacturing from day one, providing a vision for how future sustainable economies on Earth could function.

Thank you for reading! 🙏🏾

Want to reach an engaged, highly niche audience of more than 1,500 biotech x agrifood enthusiasts? If you are exploring sponsorship opportunities, reach out at eshansamaranayake@gmail.com or simply reply to this email.

Enjoyed this issue? Let me know how you think I can improve!

If the newsletter brought you value, please consider sharing it with a friend who might benefit, or making a small pledge to acknowledge the hours behind each issue. Thank you for reading and supporting my work!

Hi Eshan! Wow! What a fantastic writeup in James' newsletter! I got to know much more about you and your passion for the alt protein space. You are Sri Lankan! I've been to Hong Kong a few times. What an amazing energetic place. I live in Los Angeles and Hong Kong is like L.A. without the gangs, graffiti, and trash dumped on the street. It's both a pleasure and honor to get to know you better. Excellent issue #92! I never thought an alt leather product could be cultivated. Sooo many positive developments are happening in the space, and your readers appreciate you bringing them to our inbox every week. Okay, I have a suggestion! Put a small pic of Eshan on the top of your newsletters. I used to put my pic in my newsletters when I was the newsletter publisher at a large law firm. Thank you for taking all the time and effort to create your outstanding newsletters. Each one is a work of art. Take care and hsve a very nice and productive week 👍❤️